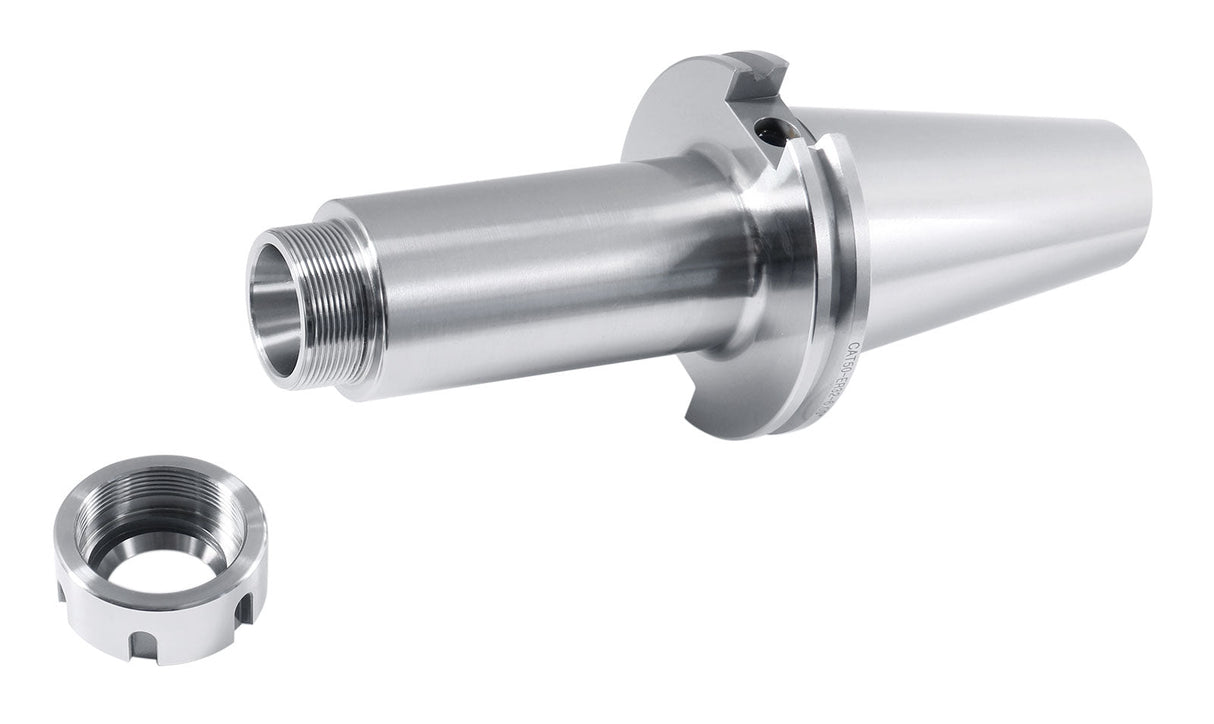

CAT50 V-Flange C.N.C. ER Collet Chucks

- Constructed of alloy steel for long, durable service life

- Hardened to HRC 52-56 to avoid damaging collet chuck threads

- Through-Spindle coolant capability

- Collet seat taper TIR < 0.0002''

- Taper: CAT50

- All critical surfaces are precision ground

- Drawbar thread: 1"-8.

- Packed in Fitted Box

| Item | Taper | Collet Series | Projection Length | Range |

| CT50-16E4 | CAT50 | ER16 | 4" | 1/32"-3/8" |

| CT50-16E6 | CAT50 | ER16 | 6" | 1/32"-3/8" |

| CT50-20E4 | CAT50 | ER20 | 4" | 1/16"-1/2" |

| CT50-20E6 | CAT50 | ER20 | 6" | 1/16"-1/2" |

| 6782-1095 | CAT50 | ER32 | 4" | 3/32"-25/32" |

| 6782-1651 | CAT50 | ER32 | 6" | 3/32"-25/32" |

| CT50-40E4 | CAT50 | ER40 | 4" | 1/8"-1" |

| CT50-40E6 | CAT50 | ER40 | 6" | 1/8"-1" |

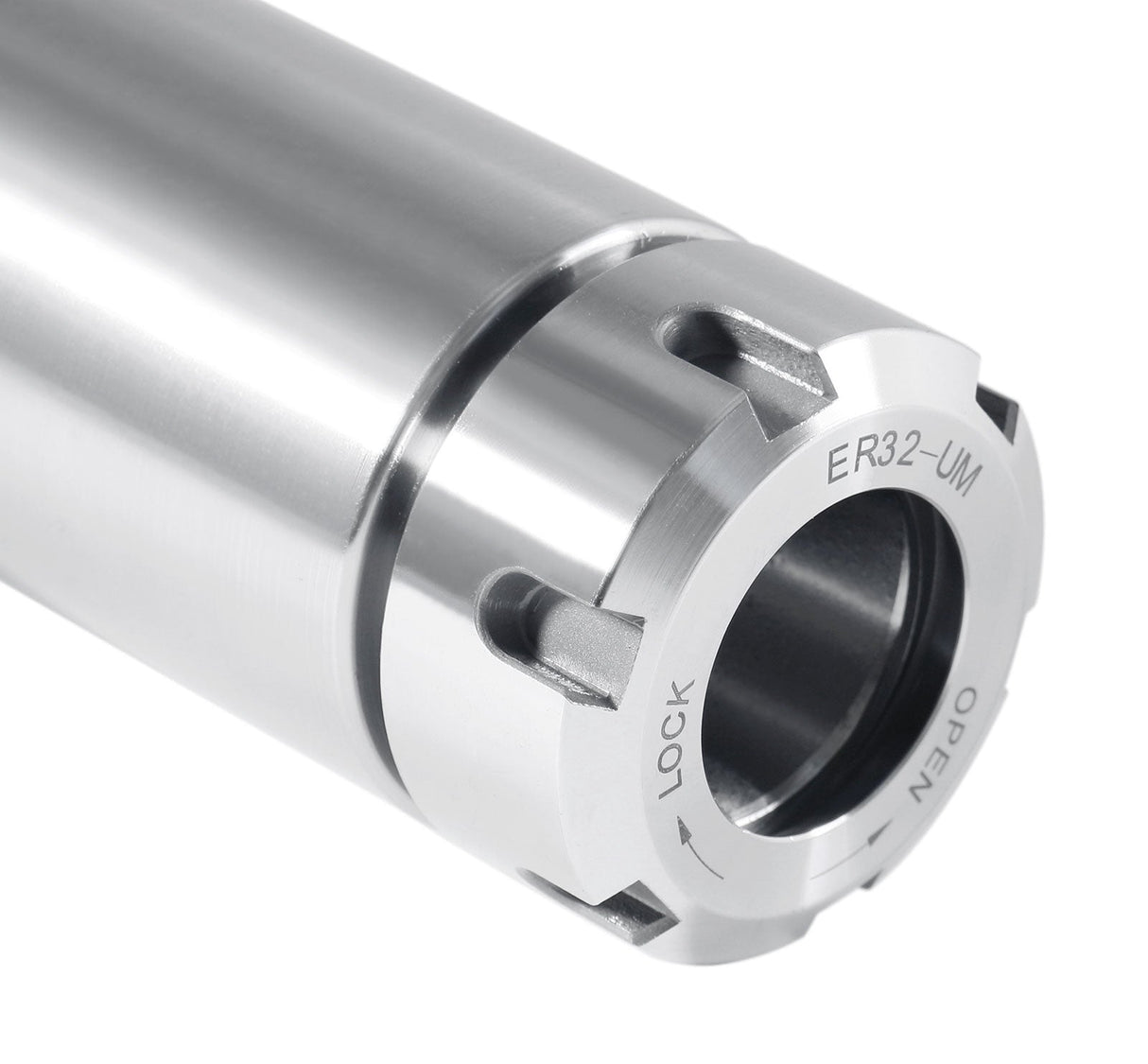

Design, Assemble, and Dissemble of ER Collet Nut

|

|

|

|

| Eccentric Design, ISO 15488:2003(E) | Assemble | Inspection | Dissemble |

| The inside of the ER collet nut is intentionally designed like off-centering to help mount the ER collet much easier. It is in accordance with the requirements listed in ISO 15488:2003(E). If it is made symmetrical, the ER collet with the diameter larger than the inside size of the collet nut cannot be installed. | Insert the ER collet into the nut at an angle. Lock it onto the eccentric groove of the collet nut and push it in. (Insert the cutter right after the step, before connect it to the holder/chuck/arbor.) |

Inspect the RPM of the ER collet, ER collet nut, ER collet holder/chuck/arbor, etc. | Take out the tool bit, press the end of the ER collet until the collet off the position. Push it out of the nut. (after take out the nut out of the holder.) |