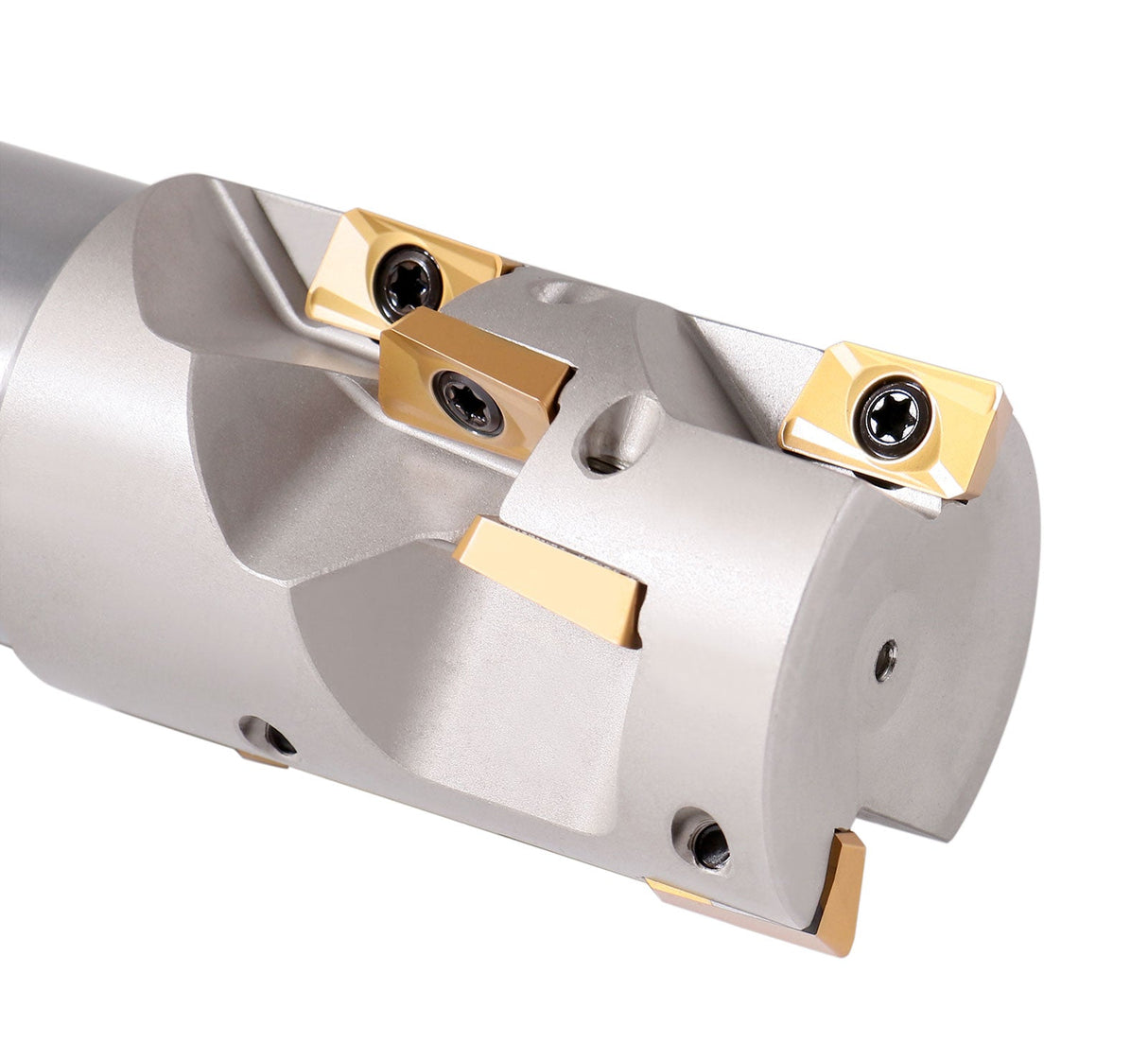

Indexable Weldon Shank End Mill, Right Hand, Heavy Duty Cut

- 90° heavy duty deep slotting

- Side milling and finish pocketing cutter

- Ideal for high speed machining with low power consumption

- Majorly used for step shoulder, slot milling, ramp milling and plunge milling. Not recommended for angle cut.

| Item | Diameter (D) | Shank Dia. (d) | Overall Length (L) | Flute Length | No of Flutes | No of Inserts | Insert Style | Screw | Key |

| 5508-0000 | 3/4" | 3/4" | 3-1/2" | 1-3/32" | 1 | 4 | APKT11T3 | M2.5 | T8 |

| 5508-0002 | 1" | 1" | 4-1/4" | 1-7/16" | 2 | 8 | APKT11T3 | M2.5 | T8 |

| 5508-0003 | 1-1/4" | 1-1/4" | 4-1/2" | 1-3/4" | 2 | 10 | APKT11T3 | M2.5 | T8 |

| 5508-0004 | 1-1/2" | 1-1/4" | 5" | 2-1/8" | 2 | 14 | APKT11T3 | M2.5 | T8 |

| 5508-0005 | 1-1/2" | 1-1/4" | 4-1/2" | 1-11/16" | 2 | 6 | APKT1604 | M4 | T15 |

| 5508-0006 | 1-3/4" | 1-1/2" | 5-1/2" | 2-1/4" | 2 | 8 | APKT1604 | M4 | T15 |

| 5508-0007 | 2" | 1-1/2" | 6" | 2-1/4" | 3 | 12 | APKT1604 | M4 | T15 |

| 5508-0008 | 2" | 1-1/2" | 6-1/2" | 2-13/16" | 3 | 15 | APKT1604 | M4 | T15 |

| 5508-0009 | 2" | 2" | 7" | 3-1/4" | 3 | 15 | APKT1604 | M4 | T15 |

Recommend Cutting Speed:

| Item No. | Description | Materials | Hardness(HB) | Cutting parameter | ||

| Indexable Weldon Shank End Mills | V(m/minï¼?/strong> | f(mm/Zï¼?/strong> | ae | |||

| 5508-0000 | 3/4x3/4" / 1 flute with 4 inserts | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 5508-0002 | 1"x1" / 2 flutes with 8 inserts | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 5508-0003 | 1-1/4" x 1-1/4" / 2 flutes with 10 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0004 | 1-1/2" x 1-1/4�/ 2 flutes with 14 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0005 | 1-1/2" x 1-1/4�/ 2 flutes with 6 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0006 | 1-3/4“x 1-1/2" / 2 flutes with 8 inserts | Low-carbon Steel | â‰?80 | 40-80 | 0.2ï¼?.1-0.2ï¼?/td> | â‰?.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0007 | 2" x 1-1/2" / 3 flutes with 12 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0008 | 2" x 1-1/2" / 3 flutes with 15 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 5508-0009 | 2" x 2" / 3 flutes with 15 inserts | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

**ABOVE CUTTING PARAMETERS PROVIDED FOR REFERENCE ONLY **