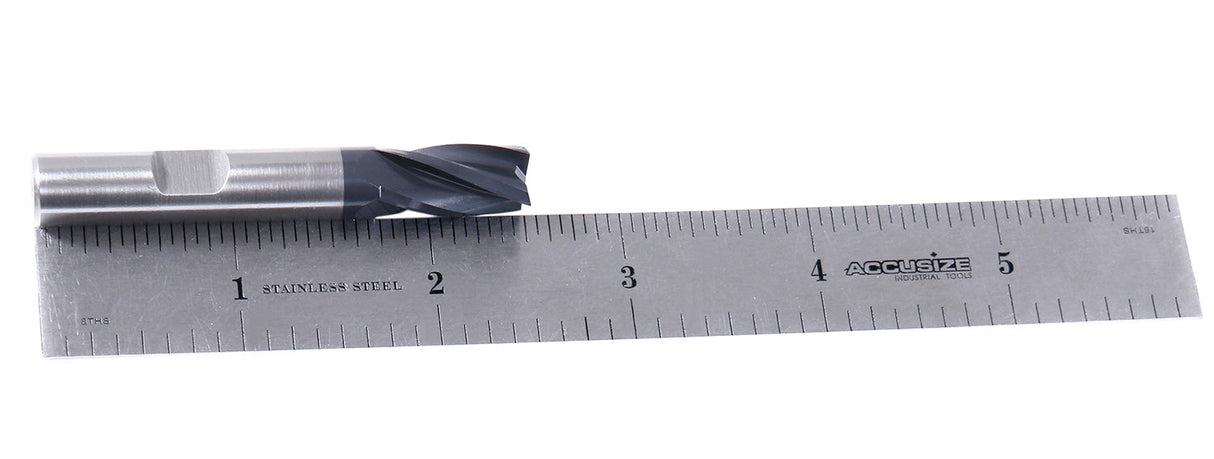

M42 (HSS+8% Cobalt) Finishing CNC End Mill, 4 Flute, TiAlN Coating

- TiAlN Coated

- Single end

- Center cutting

- M42-8% Premium cobalt

- Flutes ground by a world-class IS-9002 Factory, CNC Qualified

| Item # | Dia. | Shk. Dia. | Flt. Length | Oal. |

|---|---|---|---|---|

| 6800-4001 | 1/8" | 3/8" | 3/8" | 2-5/16" |

| 6800-4021 | 1/4" | 3/8" | 5/8" | 2-7/16" |

| 6800-4041 | 3/8" | 3/8" | 3/4" | 2-1/2" |

| 6800-4051 | 1/2" | 1/2" | 1-1/4" | 3-1/4" |

| 6800-4061 | 5/8" | 5/8" | 1-5/8" | 3-3/4" |

| 6800-4081 | 3/4" | 3/4" | 1-5/8" | 3-7/8" |

| 6800-4101 | 7/8" | 7/8" | 1-7/8" | 4-1/8 |

| 6800-4121 | 1" | 1" | 2" | 4-1/2" |

Recommended cutting speed and feed

| End mils, Side Milling[1/8"�"] Recommended Cutting Conditions | ||||||||||

| Work Material |

Low Carbon Steels(Tensile Strength: �80 N/mm2]Copper Alloys,Cast Iron(Hard) |

Medium Carbon Steels(Tensile Strength:480�/strong> 720 N/mm2]Copper Alloys,Cast Iron(Hard) |

High Carbon Steels(Tensile Strength:720�/strong> 950 N/mm2]Alloys Steel,Stainless Steels |

Special Alloy Steels /Untree‐cutting Steels(30â€?0 HRC) |

Aluminium /Aluminium Alloys /Plastic | |||||

| Mill Dia | Speed | feed | Speed | feed | Speed | feed | Speed | feed | Speed | feed |

| (inch) | (rpm) | (mm/min | (rpm) | (mm/min | (rpm) | (mm/min | (rpm) | (mm/min | (rpm) | (mm/min) |

| 1/8" | 5035 | 106 | 3800 | 81 | 2518 | 41 | 1520 | 20 | 17100 | 340 |

| 1/4" | 2518 | 151 | 1900 | 113 | 1254 | 54 | 760 | 27 | 8500 | 425 |

| 3/8" | 1425 | 202 | 1064 | 151 | 713 | 72 | 428 | 37 | 4750 | 531 |

| 1/2" | 1121 | 191 | 855 | 143 | 570 | 68 | 337 | 37 | 3800 | 502 |

| 5/8" | 903 | 170 | 675 | 128 | 451 | 68 | 266 | 38 | 2992 | 451 |

| 3/4" | 713 | 160 | 532 | 106 | 356 | 64 | 190 | 34 | 2375 | 425 |

| 7/8" | 637 | 151 | 475 | 95 | 318 | 56 | 171 | 31 | 1900 | 361 |

| 1" | 570 | 143 | 428 | 85 | 285 | 50 | 152 | 27 | 1710 | 340 |

- The Indicated speeds and feeds are

- For side milling with 2‐fluted end mill to a depth=0.1xD and a width of cut=1.5xD

- For milling with 4‐fluted, the feed should be twice that listed above.

- For finishing operations, the feed should be increased by 30�0%. 3.Use a rigid and precise machine and holder.

- Use suitable cutting fluids