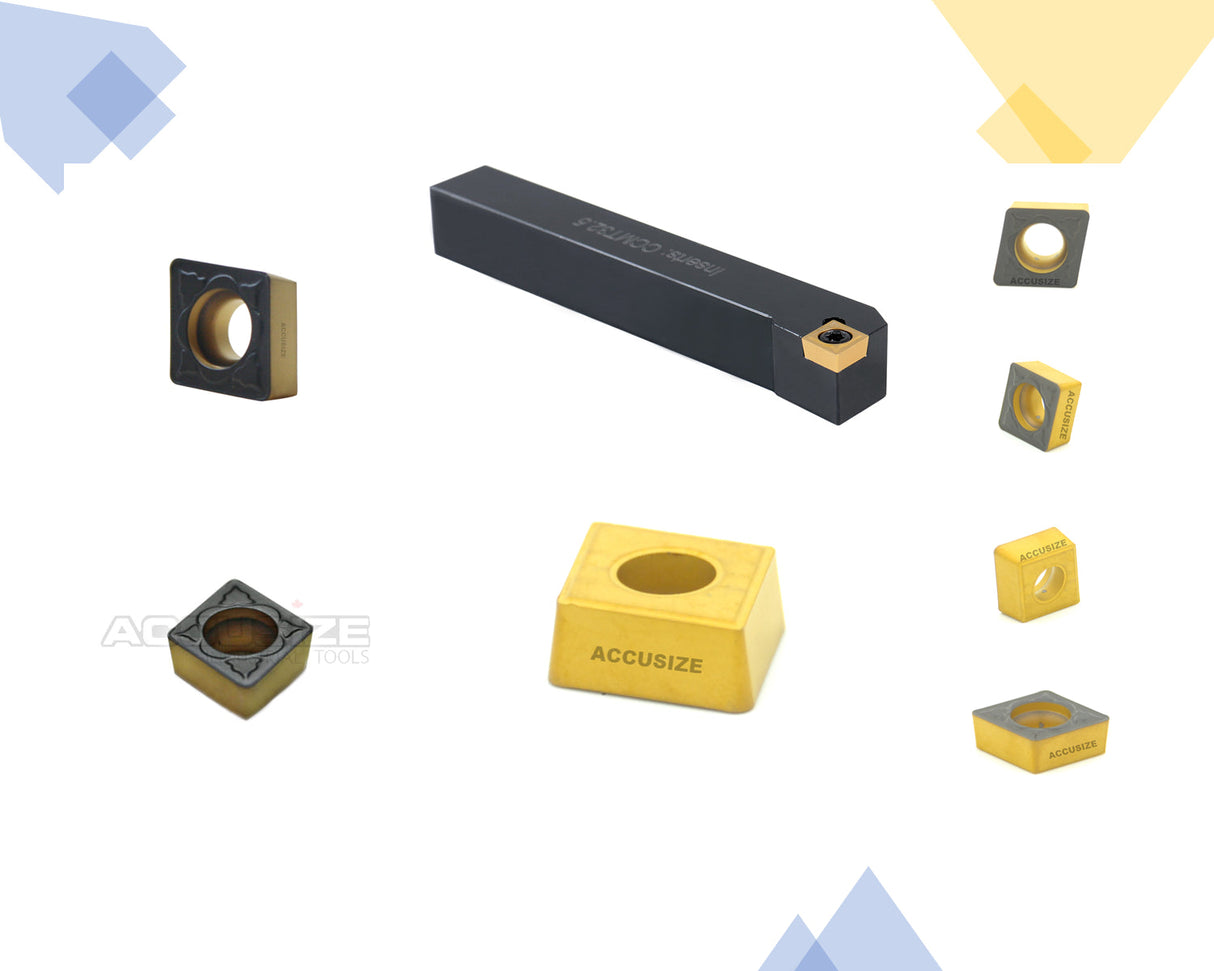

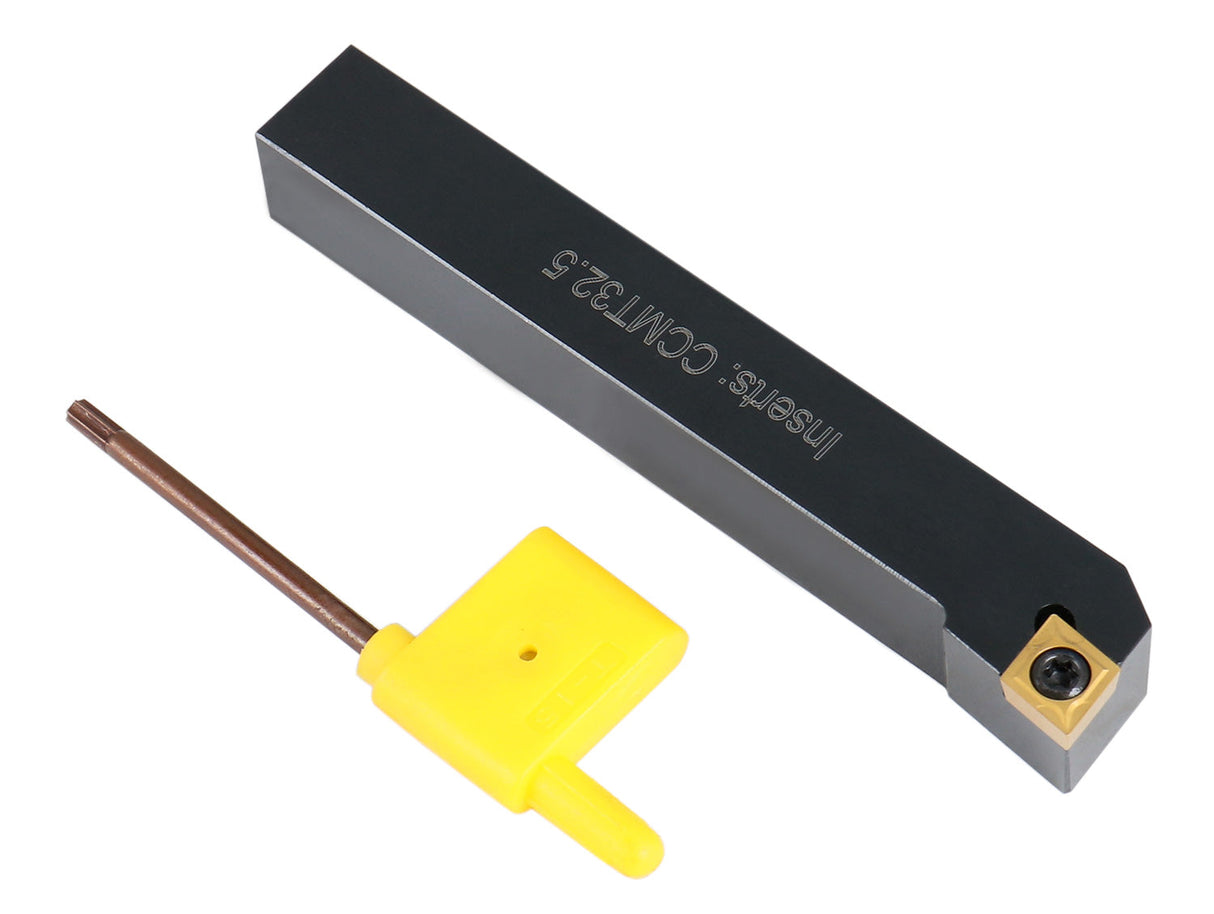

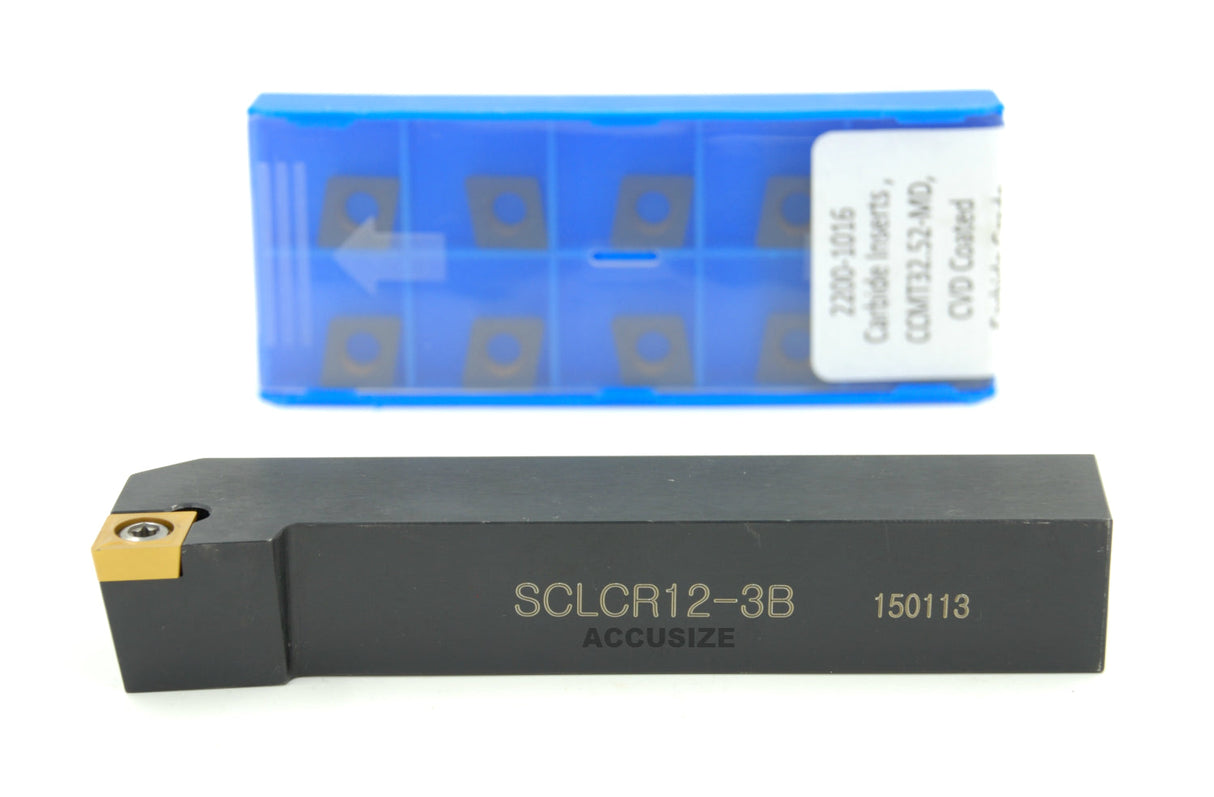

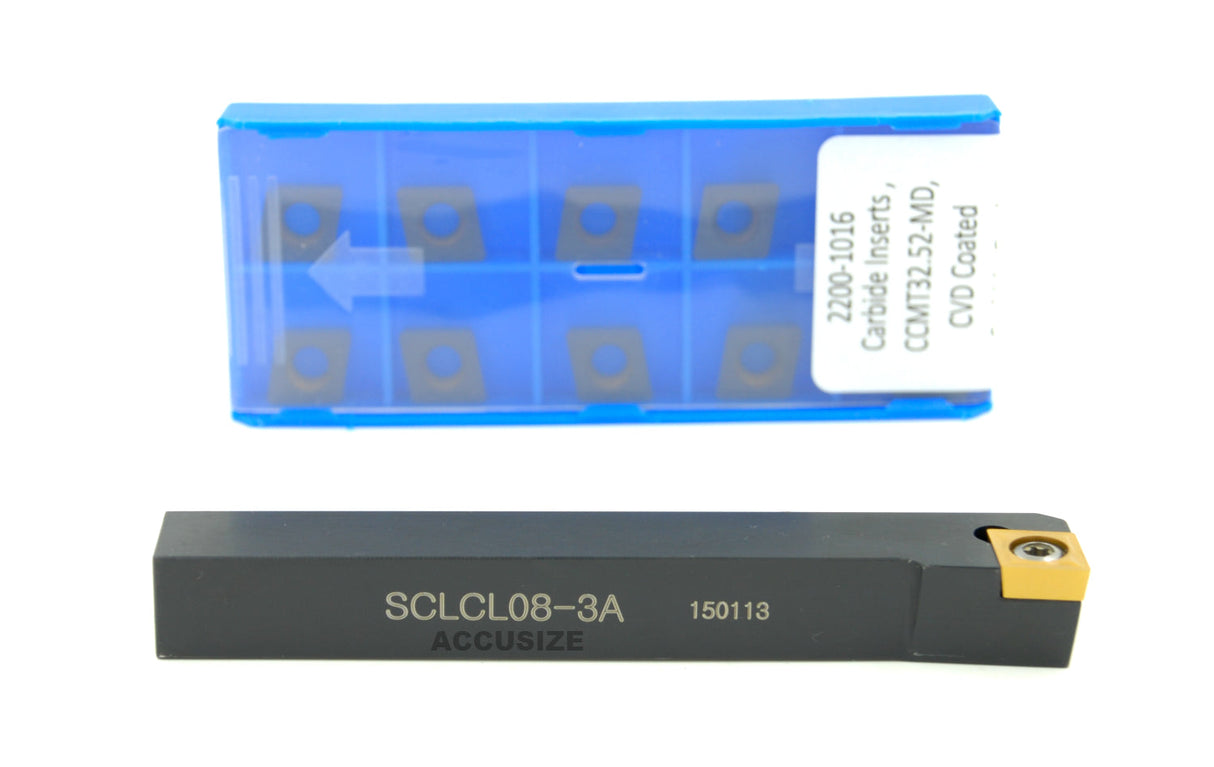

SCLC R/L Toolholders with 10 pc CCMT Carbide CVD Coated Inserts

- Negative 5° end or side cutting edge angle for positive 80° diamond CCMT CCGX inserts

| Item# | Right/Left Hand | Model | Shank Square (A & B) | C | F | Inserts |

| 2370-5004INS | Right | SCLC R -06-2J | 3/8" | 3-1/2" | 1/2" | 10 pc CCMT 21.51 |

| 2370-5006INS | Right | SCLC R -08-3A | 1/2" | 4" | 5/8" | 10 pc CCMT 32.51 |

| 2370-5008INS | Right | SCLC R -10-3B | 5/8" | 4-1/2" | 3/4" | 10 pc CCMT 32.51 |

| 2370-5010INS | Right | SCLC R -12-3B | 3/4" | 4-1/2" | 1" | 10 pc CCMT 32.51 |

| 2370-6008INS | Left | SCLC L -06-2J | 3/8" | 3-1/2" | 1/2" | 10 pc CCMT 32.51 |

| 2370-6006INS | Left | SCLC L -08-3A | 1/2" | 4" | 5/8" | 10 pc CCMT 32.51 |

|

Carbide Inserts, CVD Coating, CCMT, Black/Yellow, 10 ps/box

- Insert Style: CCMT

- 7 degree

- Insert Grade: BPS101

- Chip Breaker: MD

- Material: Carbide

- Coating: CVD Al2O3 TICN

- Machining Parts Material: Steel

- Machining Process: Finish

Product features

- BPS101 Black/Yellow Coating Grade

- CVD coated carbide grade, wear-resistance materials coated on the gradient sintered substrate which has both good hardness, toughness

- Can bear high temperatures

- For steel and steel castings finishing to roughing processing

- Continue cutting to light interrupted cutting

- Machining of gray and ductile iron at low to medium cutting speed

- For hard materials continuous cutting and light interrupted cutting from finishing to roughing

- Wet and dry processing

- Combination of fibrous TICN and fine grained Al2O3 increases abrasion resistance and anti-chipping

- Preferred choice chip breaker on General Purpose Finishing

Features of chipbreaker

- For medium-duty turning with broad capability for steel, stainless steel, grey and nodular cast-iron

- Operations: turning, facing and profiling

- Advantages: all-round, reliable with problem-free machining

- Limitations: depth of cut and feed, risk of overloading the cutting edge

- Components typically: axles, shafts, hubs, gears, etc.