90 Degree Square Shoulder Indexable End Mill w/ Carbide APKT Inserts

- 90° Cutting angle

- Screw down insert

- Radial rake angle: -10°

- Axial rake angle: +7°

- All types of square shoulder face milling, side milling and full slot milling (shaft end mills) of steels, alloyed steels, stainless and heat resistant steels, case irons and aluminum alloys.

- Fitted with 10° positive rectangular insert allow high depth of cut and feed per tooth

- Uses APKT / APHW / APKR_APHT / APMT insert (sold separately)

| Item | Cutting Diameter (D) | Shank (d1) | Oal(L) | ap | No of Inserts | Screw | Inserts |

|---|---|---|---|---|---|---|---|

| 0056-0912 | 3/8" | 1/2" | 3" | 0.433" | 1 | M2.5 x 6 | APKT11T3 |

| 0056-0913 | 1/2" | 5/8" | 3-1/4" | 0.433" | 1 | M2.5 x 6 | APKT11T3 |

| 0056-0914 | 1/2" | 1/2" | 3-1/4" | 0.433" | 1 | M2.5 x 6 | APKT11T3 |

| 0056-0916 | 5/8" | 5/8" | 3-1/4" | 0.433" | 2 | M2.5 x 6 | APKT11T3 |

| 0056-0917 | 3/4" | 3/4" | 3-1/2" | 0.433" | 3 | M2.5 x 6 | APKT11T3 |

| 0056-0920 | 1" | 1" | 3-1/2" | 0.433" | 4 | M2.5 x 6 | APKT11T3 |

| 0056-0921 | 1" | 1" | 3-3/4" | 0.551" | 2 | M4 x 8 | APKT1604 |

| 0056-0922 | 1-1/4" | 1-1/4" | 3-3/4" | 0.551" | 3 | M4 x 8 | APKT1604 |

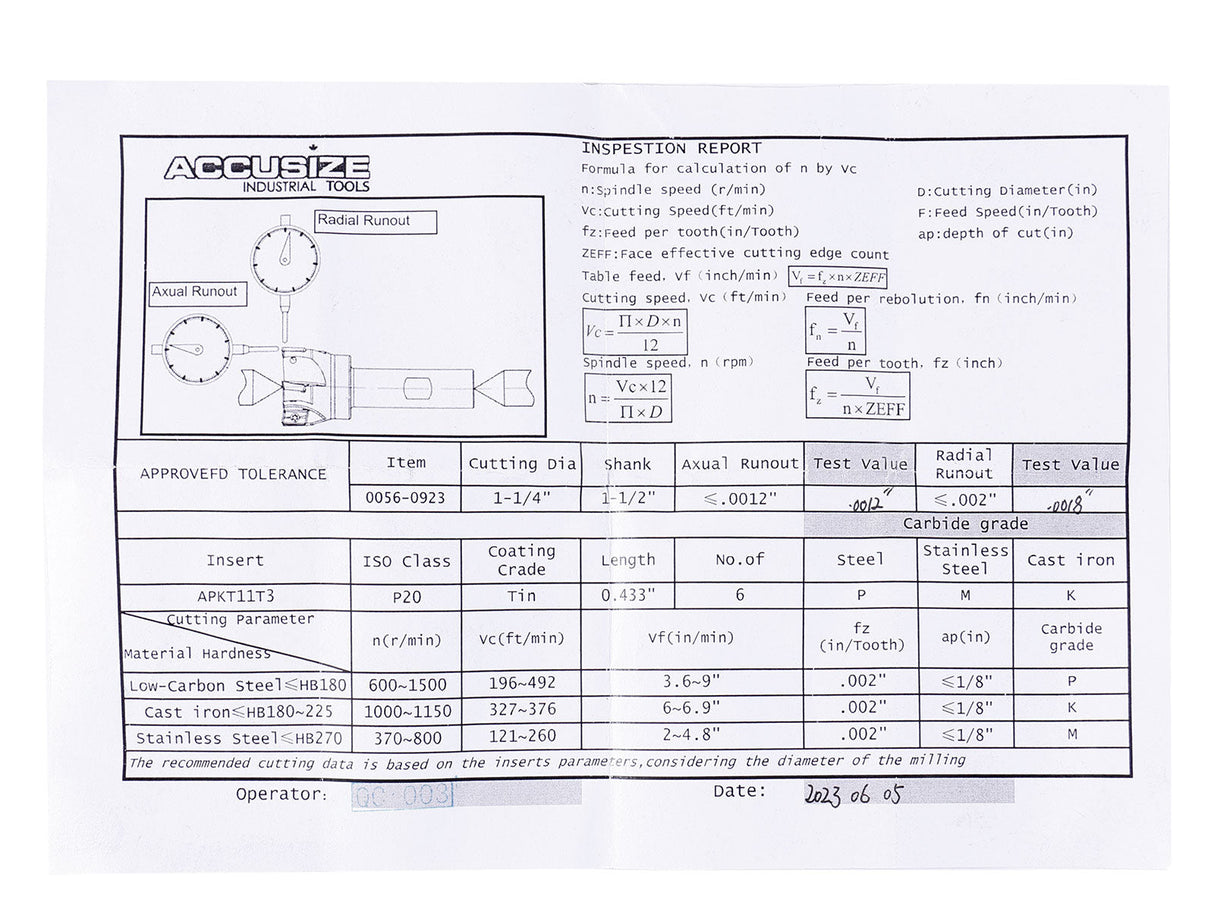

| 0056-0923 | 1-1/4" | 1-1/2" | 4-1/4" | 0.433" | 6 | M2.5 x 6 | APKT11T3 |

| 0056-0924 | 1-1/2" | 1-1/2" | 4-1/4" | 0.551" | 4 |

M4 x 8 | APKT1604 |

Recommended RPM

| Item No. | Description | Materials | Hardness(HB) | Cutting parameter | ||

| 90° Square Shoulder Indexable End Mill | V(m/minï¼?/strong> | f(mm/Zï¼?/strong> | ae | |||

| 0056-0912 | 3/8" x 1/2" shank x 3" Oal. 1 Flute, with 1 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0913 | 1/2" x 5/8" shank x 3-1/4" Oal. 1 Flute, with 1 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0914 | 1/2" x 1/2" shank x 3-1/4" Oal. 1 Flute, with 1 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0916 | 5/8"x 5/8" shank x 3-1/4" Oal. 2 Flute, with 2 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0917 | 3/4"x 3/4" shank x 3-1/2" Oal. 3 Flute, with 3 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0920 | 1"x 1" shank x 3-1/2" Oal. 4 Flute, with 4 APKT11T3 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0921 | 1"x 1" shank x 3-1/2" Oal. 4 Flute, with 4 APKT1604 insert | Low-carbon Steel | �80 | 60-120 | 0.2�.05-0.1�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 60-120 | 0.2�.05-0.1�/td> | �.5D | ||

| Tool Steel | 280-350 | 60-90 | 0.2�.05-0.1�/td> | �.5D | ||

| 0056-0922 | 1-1/4"x 1-1/4" shank x 3-3/4" Oal. 3 Flute, with 3 APKT1604 insert | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 0056-0923 | 1-1/4"x 1-1/2" shank x 4-1/4" Oal. 6 Flute, with 6 APKT11T308 insert | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

| 0056-0924 | 1-1/2"x 1-1/2" shank x 4" Oal. 4 Flute, with 4 APKT1604 insert | Low-carbon Steel | �80 | 40-80 | 0.2�.1-0.2�/td> | �.5D |

| High-carbon Steel, Alloy Steel | 180-280 | 40-80 | 0.2�.1-0.2�/td> | �.5D | ||

| Tool Steel | 280-350 | 30-60 | 0.2�.1-0.2�/td> | �.5D | ||

**ABOVE CUTTING PARAMETERS PROVIDED FOR REFERENCE ONLY **